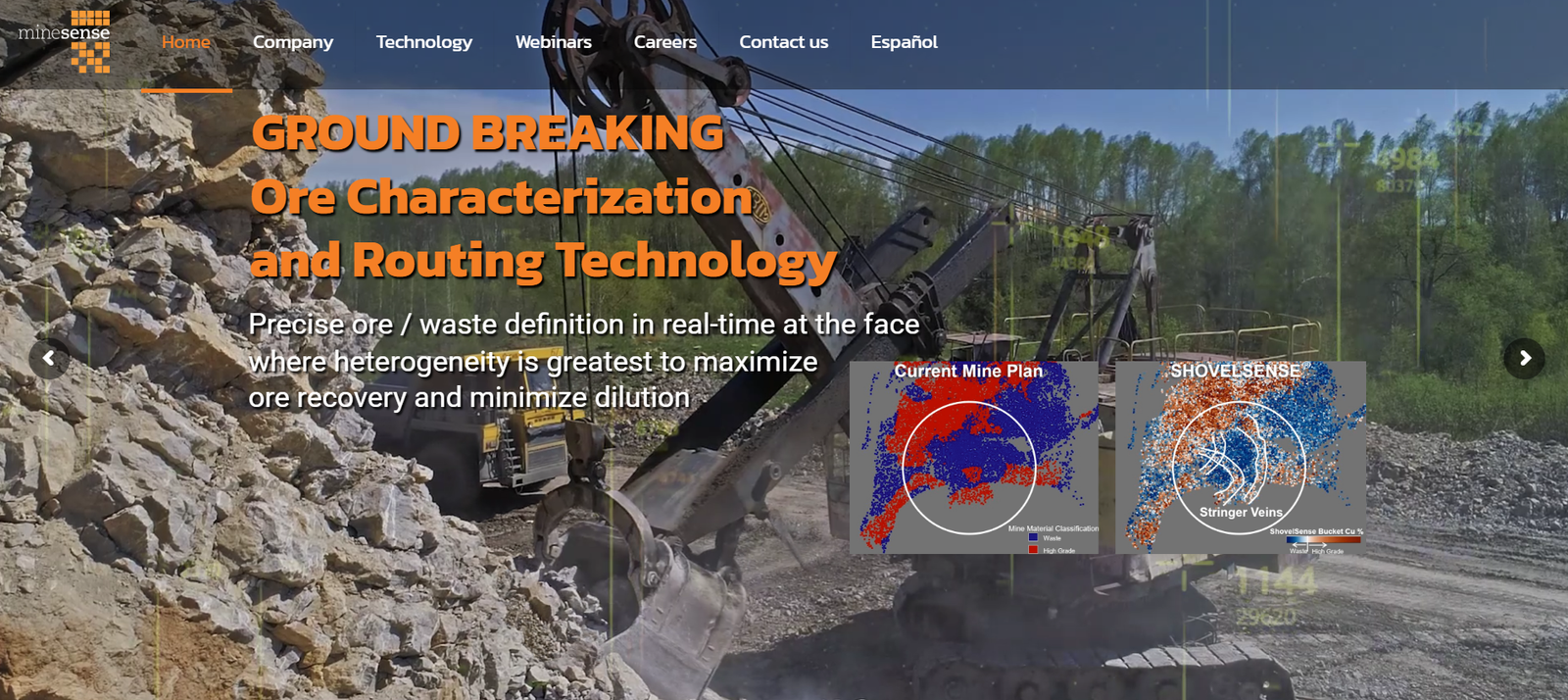

MineSense Technologies is a Canada-based mining technology company that delivers real-time, sensor-based ore sorting and data analytics solutions to increase efficiency and sustainability in mining operations. By integrating its proprietary ShovelSense® system into existing mining equipment, MineSense empowers mining companies to make data-driven decisions directly at the mine face, reducing waste and improving ore recovery.

As mining companies face mounting pressure to reduce environmental impact and improve operational economics, MineSense’s solution bridges the gap between geology and processing. It helps miners extract more metal with less waste, energy, and water—without requiring major changes to existing infrastructure.

MineSense operates globally, with deployments in major mining jurisdictions across North America, South America, and other key regions, supporting responsible resource extraction through innovation and real-time insight.

Features:

ShovelSense® System

A rugged, real-time sensing system installed on electric cable shovels that scans ore as it is mined, measuring grade and ore characteristics instantly.Real-Time Data Analytics

Provides instant feedback on ore quality, enabling miners to sort material on the spot (high-grade ore vs. waste rock).Ore Characterization at the Face

Enables data-driven decisions during material movement—before it enters the processing plant.Cloud-Based Decision Support

Offers secure, centralized data storage and visualization through MineSense’s cloud platform.Integration with Existing Equipment

Retrofits onto standard mining shovels without the need for plant modifications.Improved Ore Grade Control

Enhances mine planning and short-term production forecasting by refining knowledge of orebody variability.Sustainability Metrics

Supports ESG goals by reducing tailings, energy use, water consumption, and emissions per ton of metal produced.Interoperable Data Access

Compatible with mine fleet management systems and supports integration into digital mine platforms.

How It Works:

Sensor Installation

The ShovelSense® system is installed on the dipper of electric shovels operating at the mine face.Ore Scanning

As the shovel collects material, the system uses X-ray fluorescence (XRF) sensors to measure metal content in real time.Data Processing

Onboard analytics instantly classify the material based on metal grade thresholds.Sorting Instructions

Operators receive instant guidance (e.g., “send to mill” or “send to waste”) based on pre-set ore grade criteria.Data Storage & Reporting

All collected data is transmitted to the cloud for visualization, reporting, and integration into mine planning software.Optimization

Planners and engineers use the data to adjust blast designs, haulage routes, and plant feed strategies.

Use Cases:

Copper Mining

Optimize copper recovery by improving ore-waste classification during excavation.Polymetallic Mines

Enable multi-element detection and classification for complex ore types.Mine Planning & Grade Control

Support short-term planning with high-resolution ore body information.Sustainability & ESG Reporting

Demonstrate reduced environmental impact with measurable energy and water savings.Digital Mine Transformation

Integrate with broader smart mining platforms for full operational visibility.

Pricing:

MineSense offers customized enterprise pricing based on:

Number and type of shovel systems to be equipped

Mine size and complexity

Type of ore and metal(s) targeted

Integration and support requirements

Cloud analytics and data storage needs

MineSense works directly with mining operators to assess needs and deliver tailored solutions. Interested companies can request a consultation or demo through the official website:

https://minesense.com/contact/

Strengths:

Real-Time Ore Data at Extraction Point

Unlike traditional grade control methods, MineSense offers immediate, in-situ analysis.Operational Efficiency

Reduces dilution and improves plant feed quality without altering existing equipment drastically.Environmental Benefits

Supports resource efficiency by lowering waste generation and processing energy per ton of metal.Proven Field Deployments

Installed and operating successfully in mines across the Americas.Supports ESG Goals

Demonstrates clear improvements in energy, water, and carbon footprint per unit of metal.Enhances Profitability

Higher ore recovery and reduced processing costs contribute to bottom-line gains.

Drawbacks:

High Initial Investment

Requires upfront capital for sensor hardware, installation, and system integration.Complex Onboarding

Implementation involves change management, training, and integration with existing mine operations.Focus on Electric Cable Shovels

Limited compatibility with other types of mining equipment unless modified.Dependence on Consistent Calibration

Accuracy of real-time data requires regular sensor calibration and maintenance.Not a Consumer-Grade Solution

Tailored for medium to large-scale mining companies with sophisticated operations.

Comparison with Other Tools:

Hexagon Mining: Offers fleet and data analytics, but not real-time ore sorting. MineSense adds material characterization at the source.

OreSense (by Plotlogic): Also focuses on ore sensing but uses laser-based technology. MineSense leverages XRF and integration with shovels.

MineHub: Focuses on blockchain-based supply chain traceability, while MineSense targets operational mining data.

MinePlan (Hexagon): Provides 3D mine planning; MineSense complements it with real-time orebody validation.

Customer Reviews and Testimonials:

MineSense has received widespread recognition in the mining industry, including:

“Top 100 Global Cleantech Company” by Cleantech Group

Partnerships with leading copper producers in Chile, Canada, and Peru

Featured in World Economic Forum publications for sustainable mining

Select feedback includes:

“MineSense’s real-time data has revolutionized our ore classification process.”

“We’ve significantly reduced energy and water use per ton.”

“It’s one of the few mining technologies with measurable environmental and financial impact.”

Conclusion:

MineSense is transforming how the mining industry approaches ore sorting, resource recovery, and sustainability. With its real-time, shovel-mounted sensors and cloud analytics platform, it empowers mine operators to make smarter, faster decisions at the source—boosting efficiency and lowering environmental impact.

As mining companies face growing pressure to operate more sustainably and profitably, MineSense offers a scalable, proven solution that bridges operational performance with ESG responsibility. It is a leading example of how digital transformation and real-time data can drive the future of resource extraction.