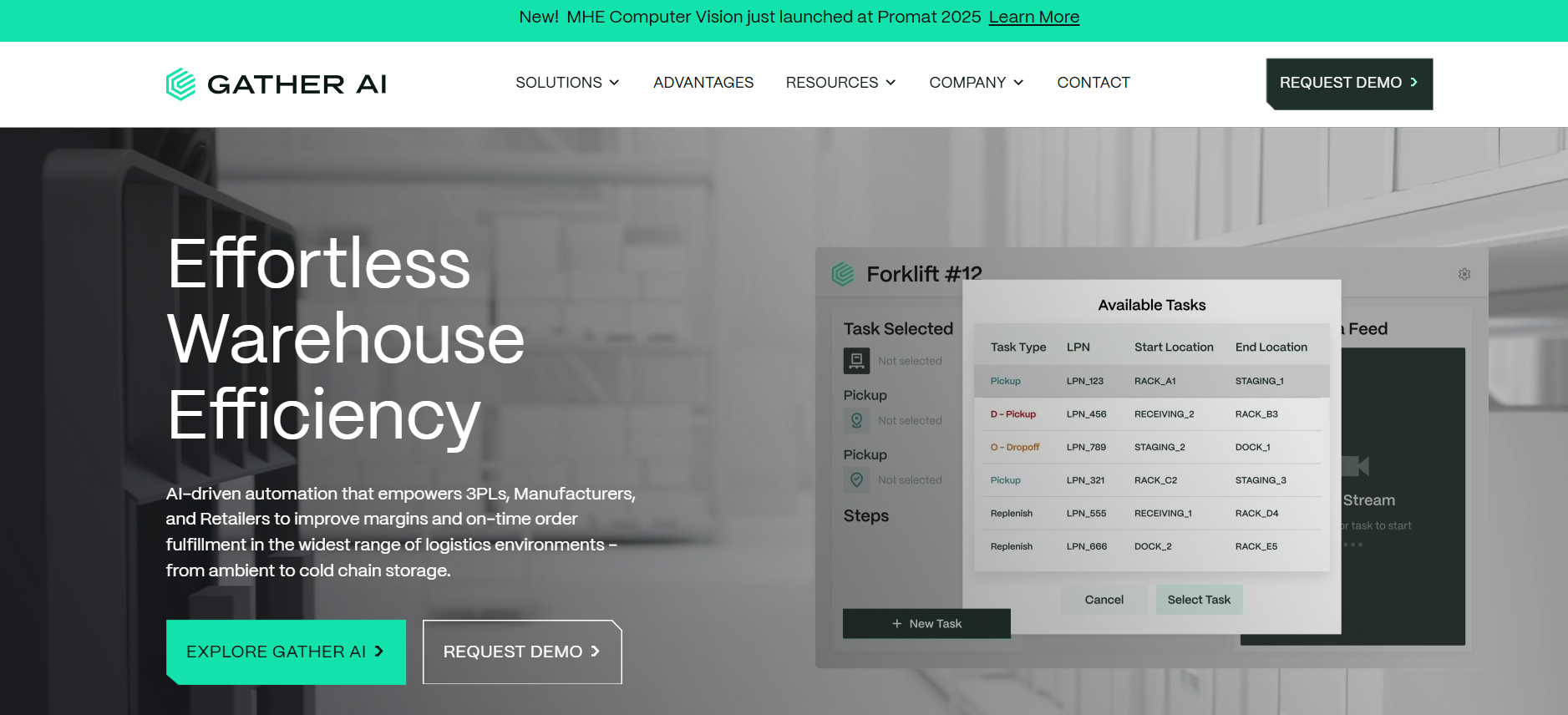

Gather AI is a cutting-edge platform that combines autonomous drones with artificial intelligence to automate inventory monitoring and management in warehouses. Built for logistics, manufacturing, and supply chain organizations, Gather AI helps teams dramatically reduce the time, cost, and errors associated with traditional manual inventory audits.

By leveraging autonomous drones that fly through warehouse aisles and capture visual data, Gather AI translates these images into actionable inventory insights—eliminating the need for manual barcode scanning, lift trucks, or spreadsheets. The platform delivers real-time visibility, analytics, and alerts, allowing warehouse teams to identify discrepancies, track stock levels, and increase operational efficiency.

Gather AI enables companies to transform their warehouses into smart, data-driven environments—without the need to reconfigure their existing infrastructure.

Features

Autonomous Drone Fleet

AI-powered drones fly autonomously within warehouse environments to capture real-time data from pallets, racks, and bins.

Visual Barcode Scanning

The drones use high-resolution cameras to scan 1D and 2D barcodes, even from varying heights and lighting conditions.

AI-Powered Analytics Dashboard

Captured images are processed using AI to detect inventory locations, identify errors, and generate actionable reports.

Cycle Counting Automation

Perform cycle counts 15x faster than manual methods while improving count accuracy.

No Infrastructure Changes Required

No need to install sensors, markers, or beacons. Drones use onboard AI to navigate existing layouts.

Web-Based Reporting Portal

Access real-time inventory data, discrepancy alerts, and historical trends from a centralized web dashboard.

Alerts and Notifications

Receive automated alerts for misplaced items, empty bins, or unexpected stock movements.

ERP/WMS Integration

Integrates with popular warehouse management and enterprise resource planning systems for seamless operations.

Multi-Site Scalability

Deploy across multiple facilities with unified monitoring and data management.

Safety-First Design

Drones are designed with warehouse safety protocols in mind, operating during off-hours or alongside staff with minimal risk.

How It Works

Gather AI transforms warehouse inventory workflows through an elegant combination of drone autonomy, AI vision, and cloud-based analytics:

Deploy Drones

Drones are assigned to specific warehouse zones and fly autonomously to scan locations based on predefined inventory maps.Capture Visual Data

As the drones fly through aisles, they capture images of barcodes, pallet labels, and shelf contents using onboard cameras.AI Processing

The images are uploaded to the cloud, where Gather AI’s algorithms process them to identify inventory status, detect errors, and interpret barcode data.Insights and Reports

Users log into the dashboard to view inventory status, alerts, and reports. Teams can verify counts, compare to WMS data, and address discrepancies.Continuous Optimization

The system improves over time by learning from corrections and operator feedback, increasing precision with each cycle.

Use Cases

Third-Party Logistics (3PL)

Enhance SLA compliance with faster and more accurate cycle counts across client inventories.

Retail Distribution Centers

Automate nightly inventory scans to keep shelf stock aligned with demand forecasts.

Cold Storage Facilities

Conduct inventory audits in low-temperature or high-rack environments where manual counts are slow and hazardous.

E-Commerce Warehouses

Keep pace with rapid SKU turnover and minimize stockout risks by increasing inventory count frequency.

Manufacturing Storage Areas

Maintain tight control over raw materials and finished goods with real-time location insights.

Pricing

Gather AI offers customized pricing based on:

Size of warehouse or number of sites

Number of drones deployed

Data processing and storage requirements

Integration and onboarding needs

To receive a tailored quote or schedule a demo, interested organizations can contact the sales team at: https://www.gather.ai/request-a-demo

Strengths

Time Savings

Drones complete cycle counts up to 15x faster than manual processes, freeing staff for higher-value tasks.

No Infrastructure Overhead

Unlike RFID or fixed camera systems, Gather AI requires no infrastructure changes—just drones and cloud software.

Accurate and Auditable Data

All scans are backed by visual proof, ensuring verifiability and transparency in inventory reporting.

Improved Safety

Reduces the need for forklifts and working at heights during manual counts, improving worker safety.

Scalable Across Locations

Deployable in multiple warehouses with consistent reporting and centralized oversight.

AI-Enhanced Insights

The platform doesn’t just scan—it interprets, learns, and improves accuracy over time through machine learning.

Drawbacks

Requires Drone-Friendly Layouts

Warehouses must have sufficient space for safe drone flight paths and may need minor operational adjustments.

Initial Setup and Mapping

A one-time mapping and calibration process is required before full automation begins.

Limited to Visual Identification

Currently focused on visible labels and barcodes; does not support non-visual item tracking like RFID.

Not Ideal for Very Small Warehouses

ROI is best realized in medium to large warehouses where manual inventory tracking is more time-intensive.

Comparison with Other Tools

Gather AI vs. Manual Cycle Counting

Manual counting is slow, error-prone, and labor-intensive. Gather AI is faster, safer, and more accurate.

Gather AI vs. RFID Systems

RFID requires significant infrastructure investment and tag costs. Gather AI works with standard barcodes and existing layouts.

Gather AI vs. Fixed Camera Systems

Fixed cameras require warehouse-wide installations. Gather AI uses mobile drones, offering more flexibility and lower upfront costs.

Gather AI vs. Other Drone Startups

Unlike drone-based inspection tools, Gather AI is built specifically for warehouse inventory automation, making it more specialized and effective in this niche.

Customer Reviews and Testimonials

Gather AI is trusted by logistics providers, Fortune 500 companies, and enterprise warehouse operators:

“Gather AI has saved us hundreds of hours in cycle counting and significantly reduced our inventory errors.”

— Warehouse Manager, 3PL Provider

“We used to need forklifts and teams of three just to verify one aisle. Now we get better data in minutes.”

— Director of Operations, Retail DC

“It’s like having a full-time inventory auditor in the sky, but without the overhead.”

— Logistics VP, E-Commerce Company

Several video case studies and customer stories are available on the Gather AI website.

Conclusion

Gather AI is redefining inventory management with a combination of autonomous drone technology and artificial intelligence, offering unmatched speed, accuracy, and safety in warehouse environments. Whether you’re managing a high-volume distribution center or a complex logistics network, Gather AI enables you to scale operations while minimizing labor and error rates.

For warehouses ready to modernize inventory tracking and take the leap into intelligent automation, Gather AI provides a proven, scalable, and future-ready solution.